|

The Distillation_Column is a separation equipment which simulates a rigorous multi-stage multi-component single

distillation column. It allows up to four feeds connected to

different stages of the column and up to two optional side extractions.

Total or partial condenser and partial reboiler are implemented. When partial condenser

is selected, the distillate is withdrawn vaporized. Murphree efficiency allows for non-equilibrium behavior on each stage. The total condenser

and the reboiler are considered equilibrium stages and therefore the Murphree efficiency

is taken 1.

The liquid and vapor phases flow rates and properties are listed in the Report

tab and can be optionally exported in a text file format by click on the Export

to .txt File button.

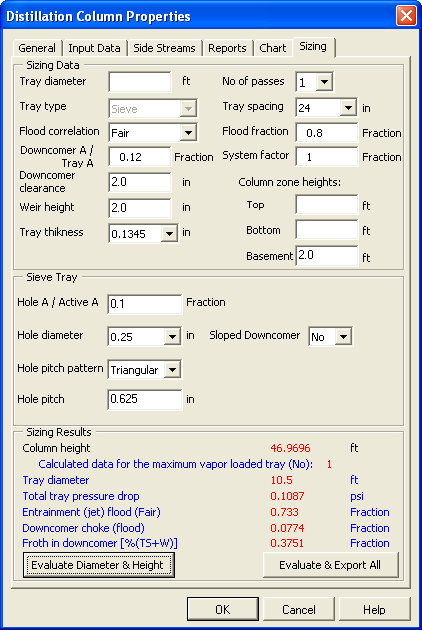

The Sizing tab optionally calculates the diameter, height and tray layout

parameters for the maximum vapor loaded tray by click on the Evaluate Diameter &

Height button. The calculations can be optionally exported in a text file format

by click on the Evaluate & Export All button. At least one run of the column is needed to accomplish these.

At least one feed stream should be connected and filled

with solvents at Feed1, Feed2, Feed3 or Feed4 connector. The Distillate_Out, Bottom_Out

and the utilities streams Coolant_In, Coolant_Out, Steam_In, Condensate_Out are

not optional. The Input Data and Side Streams Tabs should be properly filled in

before run.

|

What do you want to see?

|

|

(Colapse/Expand Data Description)

(Colapse/Expand Data Description)

|

Data |

Unit |

Description |

|

Set |

Item |

Type |

Native |

|

Equipment Properties |

NoOfStages |

|

|

The number of actual stages in the column. |

|

Reflux Ratio |

Fraction or Percent |

Fraction |

Fraction representing the top recirculation liquid flow. |

|

DistillateRate |

|

|

The flow extracted as top product in kg-moles/hr. |

|

HeatLosses |

Fraction or Percent |

Fraction |

The total heat loss of the column, fraction of the reboiler heat duty. Default value

is 0.0. |

|

CondenserType |

|

|

Selected

Total Condenser or Partial Condenser option in the Input Data tab. The partial condenser delivers

vaporized distillate product. |

|

TCondenser |

Temperature |

F |

The outlet temperature for the cooling medium in the top. |

|

ReboilerOpt |

|

|

Selected

Heating Out Temperature or Saturated Condenser option in the Input Data

tab. Set the temperature

condition of the Condensate_Out stream to be user selected or liquid saturated temperature. |

|

TReboiler |

Temperature |

F |

The outlet temperature for the heating medium (bottom). |

|

RebPresDrop |

Pressure |

psia |

The pressure drop in reboiler on the heating medium side (usually steam pressure

drop).

|

|

MaxIter |

|

|

Maximum number of iteration for the column solver algoritm. Default value is 100

iterations. |

|

SolvingMethod |

|

|

Column solving method option. Bubble Point (Wang & Henke) Method is impletented

in. |

|

VBFormOK |

|

|

Stores the overall status of the input data when the user interface window is left. |

|

SideStreams |

Feed1OnStage |

|

|

The Feed1 connection stage number. |

|

Feed2OnStage |

|

|

The Feed2 connection stage number. |

|

Feed3OnStage |

|

|

The Feed3 connection stage number. |

|

Feed4OnStage |

|

|

The Feed4 connection stage number. |

|

SideDraw1OnStage |

|

|

The Side_Draw1 connection stage number. |

|

SideDraw1Flow |

|

|

The input total flow extracted from the Side_Draw1 connector in kg-moles/hr. |

|

SideDraw1Phase |

|

|

The selected Liquid or Vapor phase of the extracted Side_Draw1 stream. |

|

SideDraw2OnStage |

|

|

The Side_Draw2 connection stage number. |

|

SideDraw2Flow |

|

|

The input total flow extracted from the Side_Draw2 connector in kg-moles/hr. |

|

SideDraw2Phase |

|

|

The selected Liquid or Vapor phase of the extracted Side_Draw2 stream. |

|

StageInputData |

StageEfficiency |

|

|

Array containing the input values of the Murphree efficiency on each stage inside

the column. The condenser and the reboiler are considered equilibrium stages and

the Murphree efficiecy is taken 1 for them. Default value is 1. |

|

StagePressure |

|

|

Array containing the input values of the pressure on each stage inside the column.

Default value is 0 psig |

|

Stage Estimated Properties |

StageTemperatureEst |

|

|

Array containing the input values of the temperature on each stage inside the column

,used as first guess for the solving algorithm of the column. Default value is 32.0

F |

|

StageLiquidEst |

|

|

Array containing the input values of the liquid load on each stage inside the column,

used as first guess for the solving algorithm of the column. Default value is 0

kg-moles/hr. |

|

StageVaporEst |

|

|

Array containing the input values of the vapor load on each stage inside the column,

used as first guess for the solving algorithm of the column. Default value is 0

kg-moles/hr. |

|

Reports |

|

Condenser Duty |

Energy Flow |

BTU/hr |

The condenser heat that is removed by the coolant. |

|

Reboiler Duty |

Energy Flow |

BTU/hr |

The reboiler heat that is supplied by the heating medium (steam). |

|

HeatLossesCalc |

Energy Flow |

BTU/hr |

The heat losses of the column (the units will be the energy flow units, e.g. mmbtu/h). |

|

Steam per Feed |

|

|

The amount of steam required per 100 mass units of feed, e.g. 5 kg of steam per

100 kg of feed.

|

|

Reflux Rate |

Mass flow |

Flbs/hr |

Mass flow of the liquid reflux returned at the top of the column. |

|

Basis |

|

|

Selected Mole Basis or Mass Basis option to display the tray loading flows in the

report grid and in the exported text file. |

|

StagePhase |

|

|

Selected Liquid, Vapor or Both phase optionin the Reports tab to display the mass

rate of the components (each solvent and other species) in the report and

in the exported text file. |

|

StageTemperature |

|

|

Array containing the calculated temperature in F on each stage inside the column,

displayed in he reports grid or in the exported text file. |

|

StageLiquidMolarFlow |

|

|

Array containing the calculated liquid molar flow in kg-moles/hr on each stage inside

the column, displayed in he reports grid or in the exported text file. |

|

StageVaporMolarFlow |

|

|

Array containing the calculated vapor molar flow in kg-moles/hr on each stage inside

the column, displayed in he reports grid or in the exported text file. |

|

validSolventList |

|

|

Array containing the list of the solvents present on each tray. |

|

StageLiquidComposition |

|

|

Array containing the mole fraction of the solvents in the liquid phase on each stage. |

|

StageVaporComposition |

|

|

Array containing the mole fraction of the solvents in the vapor phase on each stage. |

|

StageKValuesList |

|

|

Array containing the equilibrium distribution ratio of each solvent between the

liquid and the vapor phases. |

|

StageLiquidDensity |

|

|

Array containing the stage liquid density on each stage. |

|

StageVaporDensity |

|

|

Array containing the vapor phase density on each stage. |

|

DataTypeIndicator |

|

|

|

Indicates the units of measure of some internal variables. |

|

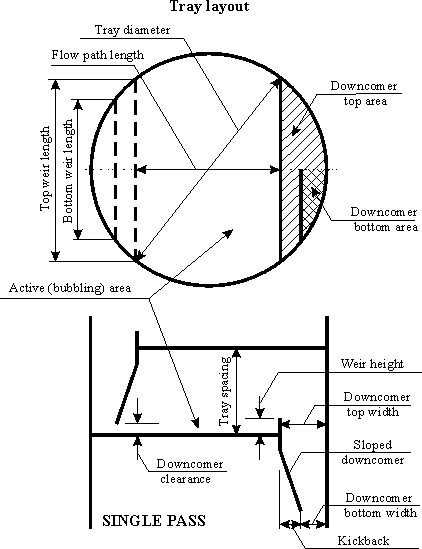

Sizing Data |

TrayDiameter |

Length |

ft |

The column internal diameter. The input value will be used on each tray (stage)

to calculate the hydrauluc and tray layout parameters, both for the maximum vapor

loaded tray in the Sizing Results frame and in the export text file . If the cell

is feft blank, the diameter wil be calculated, both for the maximum vapor loaded

tray in the Sizing Results frame and in the export text file. It is left blank by

default. |

|

TrayType |

|

|

Selected combo box option for Sieve, Valve or Bubble Cap trays (stages). |

|

FloodCorrelation |

|

|

Selected combo box option for the flodding fraction correlation used: Fair, Kister&Haas,

Smith et.al. Fair correlation is used by default. |

|

DCAreaRatio |

Fraction or Percent |

Fraction |

Downcomer Top Area to Column Area ratio. Default value is 0.12 Fraction. |

|

DCClearance |

Thickness |

in |

The Downcomer clearance is the height of the space between the tray deck and the

upper tray downcomer apron. Default value is 2 inches. |

|

DCWeirHeight |

Thickness |

in |

The Downcomer weir height. It maintains the liquid layer on the tray. Default value

is 2 inches. |

|

TrayThicknessMeasure |

Thickness |

in |

The tray deck thickness. Selection can be made among common industrial values in

a combo box or user input values may be used. Default value is 0.1345 inches. |

|

NoPasses |

|

|

The number of passes (1 to 5) of the cross flow on a tray. Default value is 1 pass. |

|

TraySpacing |

Thickness |

in |

The distance between two succesive tray decks. Selection can be made among common

industrial values in a combo box or user input values may be used. Default

value is 24 in.

|

|

FloodFraction |

Fraction or Percent |

Fraction |

Fraction of the flooding velocity of the vapor in side the column used to calculate

the tray diameter.Default value is 0.8 Fraction. |

|

SystemFactor |

Fraction or Percent |

Fraction |

Fraction indicating the foaming tendency of the liquid mixture on the tray. Default

value is 1, indicating non foaming system. |

|

ColumnTopHeight |

Length |

ft |

The top zone of the column above the upper tray (stage). If the Top and the bottom

Column zone heights are left both blank, the default 15% column volume supplement

will be used to calculate these values.

|

|

ColumnBottomHeight |

Length |

ft |

The bottom zone of the column below the flower tray (stage). If the Top and the

bottom Column zone heights are left both blank, the default 15% column volume supplement

will be used to calculate these values.

|

|

ColumnBasementHeight |

Length |

ft |

The height of the basement support of the column. Default value is 2 ft. |

|

STHoleAreaRatio |

Fraction or Percent |

Fraction |

The open area fraction of the sieve tray. It is equal with the total hole area to

column internal area ratio. Default value is 0.1 Fraction. |

|

STHoleDiameter |

Thickness |

in |

The diameter of a single hole of the sieve tray. Default value is 0.25 inches. |

|

STHolePitchPattern |

|

|

Selected pattern of the holes arrangement on the sieve tray from a combo box. Triangular

or Square pattern are used. Default pattern is Triangular. |

|

STHolePitch |

Thickness |

in |

The pitch distance of the holes arrangement on the sieve tray. Default value is

0.625 inches. |

|

STSlopedDowncomer |

|

|

No (default) or Yes selection from a combo box if the downcomer is straight or sloped

for a sieve tray. |

|

STSlopeDCAreaRatio |

Fraction or Percent |

Fraction |

The downcomer top to bottom area ratio when the Yes option is selected for the Sloped

downcomer of the sieve tray. Default value is 2 Fraction. |

|

VTHoleAreaRatio |

Fraction or Percent |

Fraction |

The open area fraction of the svalve tray. It is equal with the total aperture area

to column internal area ratio. Default value is 0.1 Fraction. |

|

VTValveType |

|

|

Selected type of the valve from a combo box. Default type is V1. |

|

VTValveMaterial |

|

|

Selected type of the valve material from a combo box. Default material is stainles

steel (S.S.). |

|

VTValveThicknessMeasure |

Thickness |

in |

The valve thickness selected value from common industrial values in a combo box

or user input values.Default value is 0.1345 inches.

|

|

|

|

|

No (default) or Yes selection from a combo box if the downcomer is straight or sloped

for a valve tray.

|

|

|

Fraction or Percent |

Fraction |

The downcomer top to bottom area ratio when the Yes option is selected for the Sloped

downcomer of the valve tray. Default value is 2 Fraction. |

|

BCTCapAreaRatio |

Fraction or Percent |

Fraction |

The open area fraction of the bubble cap tray. It is equal with the total apperture

area to column internal area ratio. Default value is 0.1 Fraction. |

|

BCTCapOD |

Thickness |

in |

|

|

BCTCapPitchPattern |

|

|

Selected pattern of the bubble caps arrangement on tray from a combo box. Triangular

or Square pattern are used. Default pattern is Triangular. |

|

BCTCapPitch |

|

|

The pitch distance of the bubble caps arrangement on the sieve tray. Default value

is ... inches. |

|

BCTSlotTopWidth |

|

|

|

|

BCTSlotBottomWidth |

|

|

|

|

BCTSlotBottomWidth |

|

|

|

|

BCTSlotSkirtHeight |

|

|

|

|

BCTStaticSeal |

|

|

|

|

BCTSlopedDowncomer |

|

|

No (default) or Yes selection from a combo box if the downcomer is straight or sloped

for a bubble cap tray. |

|

BCTSlopeDCAreaRatio |

Fraction or Percent |

Fraction |

The downcomer top to bottom area ratio when the Yes option is selected for the Sloped

downcomer of the bubble cap tray. Default value is 2 Fraction. |

|

Sizing Results |

VLoadMaxStage |

|

|

The tray (stage) number where the maximum vapor load corrected with the density

influence is detected. |

|

ColumnHeight |

Length |

ft |

The calculated column height including the tray deck thicness, top, bottom and basement

zones. |

|

CalcTrayDiameter |

Length |

ft |

The calculated tray diameter for the maximum vapor loaded tray (stage). If an input

value is detected for the diameter, tha same value will be assigned to the calculated

diameter. |

|

TotalTrayPressureDrop |

Pressure Change |

psi |

The calculated pressure drop on a wetted tray. |

|

FloodFairFraction |

Fraction or Percent |

Fraction |

The calculated flood fraction for the calculated tray diameter using the Fair's

flodding correlation. |

|

DCChokeFraction |

Fraction or Percent |

Fraction |

The downcomer choke fraction using the Koch residence time correlation and the calculated

diameter. |

|

FrothInDCFraction |

Fraction or Percent |

Fraction |

The aerated liquid mass mass (froth) as fraction of the downcomer height. |

(Colapse/Expand Equipment Properties)

(Colapse/Expand Equipment Properties)

| |

|

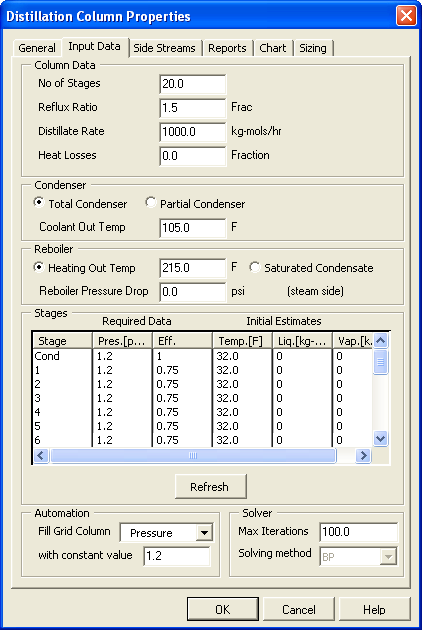

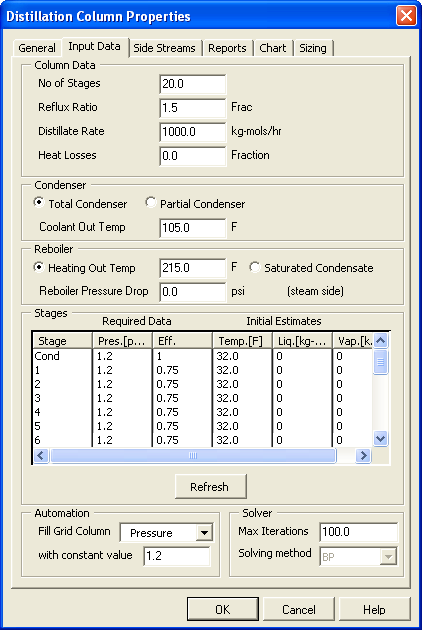

- Input Data tab. Specifies the main input data for the equipment.

- No of Stages mandatory dialog box represents

the actual number of stages (trays) inside the column. The condenser

and the reboiler are not taking into account.

- Reflux Ratio mandatory dialog box represents the

fraction of the top product returned from the condenser as liquid phase on the upper

tray inside the column.

- Distillate Rate mandatory dialog box represents

the total flow rate extracted as top product.

- Heat Losses mandatory dialog box represents the

total heat loss of the column as fraction of the reboiler heat duty.

- The distillate will be delivered as liquid phase at boiling point if Total Condenser is selected or vaporized,

if Partial condenser is selected.

- The Initial Estimates for the

column profiles used by the solver algorithm are displayed in the Stages dialog grid.

You can modify any value and then click the Refresh button with the mouse

or select it with [TAB] and press [ENTER].

- To fill a column with the same value you have to select the desired parameter in

the Fill Grid Column combo

box, input the value below and click the Refresh button.

- Increasing the number of Max Iterations the computational time

will increase. Decreasing it, the model might not converge. The final results are

the ones obtained at the end of the last iteration.

|

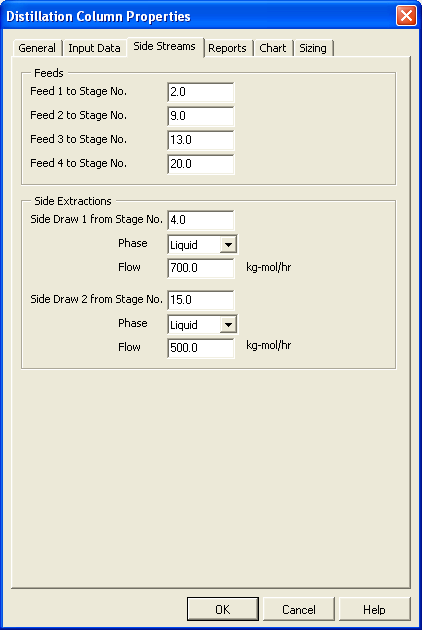

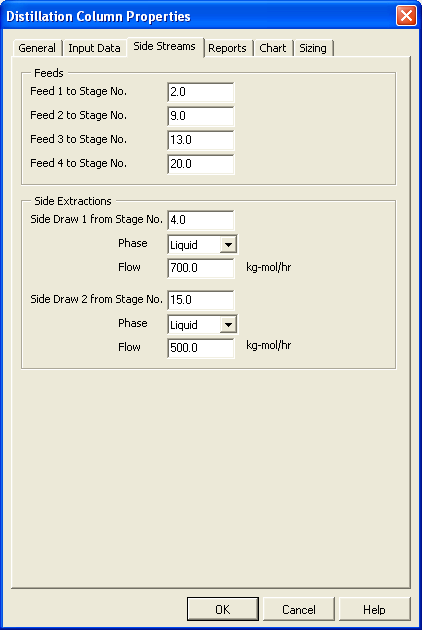

- Side Streams tab. Specifies the input data for the side streams

actually connected to the equipment.

- At least one feed stream should be connected to the equipment. Then the appropriate

mandatory dialog box should be filled with assigned number of stage to the connected

streams. Maximum 4 feed streams can be connected. The feed connectors are placed

on the same side of the equipment.

- Maximum 2 optional Side streams can be connected to the equipment to extract distillation

product from intermediate stages, either from the liquid or from the vapor phase.

The Side Draw 1 from Stage No. and Side Draw 1 from Stage

No. are mandatory dialog boxes. They should be filled in to may perform

an appropriate run of the equipment, if side streams are connected.

|

|

|

|

| |

|

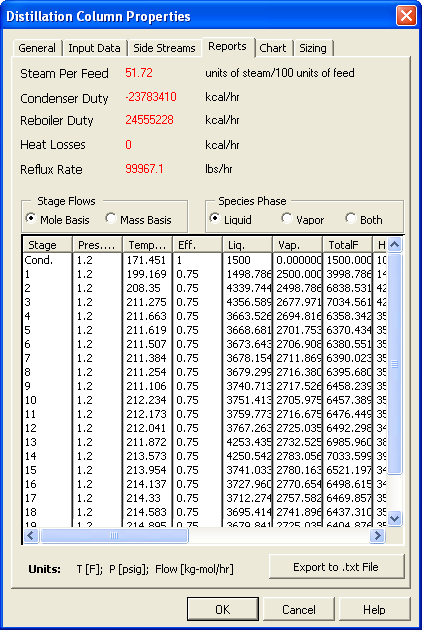

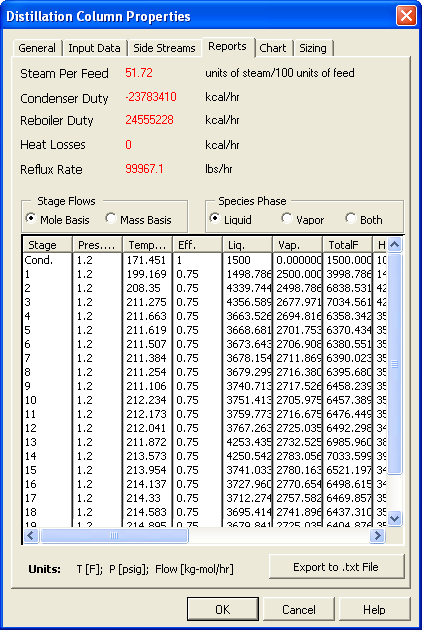

- Reports tab. Display the output results and column parameters profiles

from the distillation process calculation. The grid display the mass flow rates

on each tray: total flow, liquid phase flow, vapor phase flow, each solvent flow

and cumulated total flow of all the other components if exist. The units of measure

are displayed at the bottom of the grid.

- Select either Mole Basis or Mass Basis

|

| |

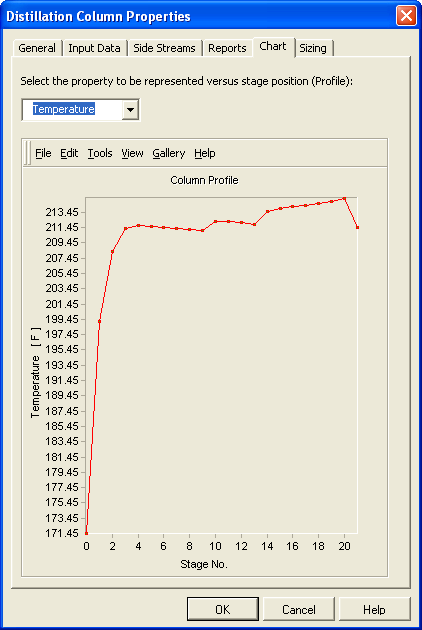

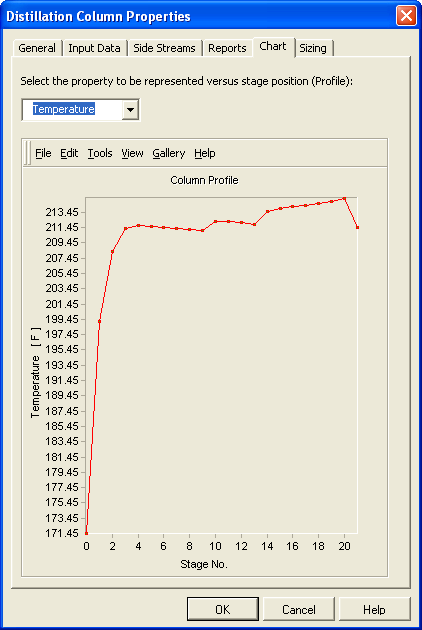

- Chart tab. Display a number of output column parameter profiles in a friendly graphical form.

The following parameters' profiles: Temperature, Pressure, Total Loading, Liquid Loading, Vapor Loading can be selected

in the combo box.

The Temperature parameter is selected by default.

- The enhanced features of the chart can be selected from the tool bar. Chart saving, printing, copying to the

Clipboard in several formats to export in other applicatications, font type and format changing, Data Editing, 3D/2D display,

gallery options and help using the chart are now available.

|

|

|

|

| |

|

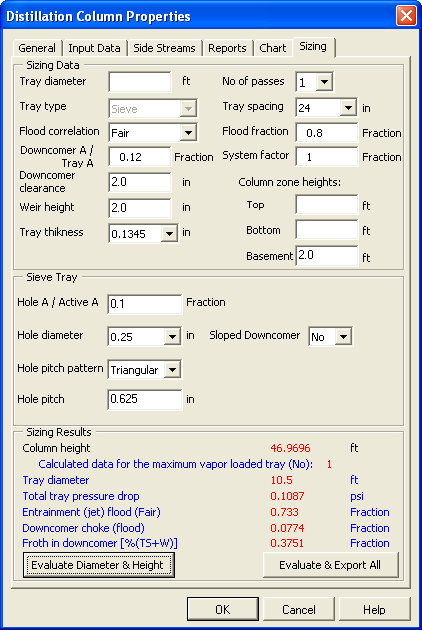

- Sizing tab. Display the general input data for the hydraulics and layout of the trays

inside the column, Sieve, Valve

or Bubble Cap input parameters and the caclulated data.

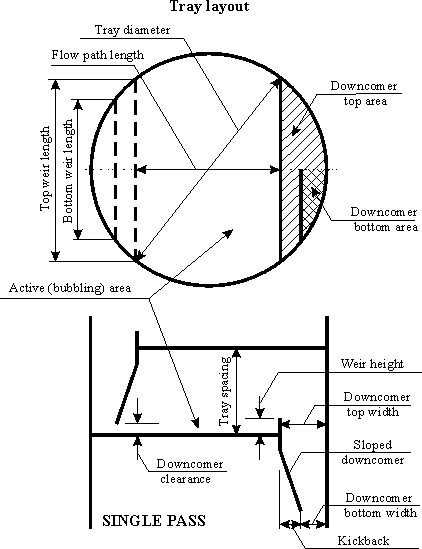

- Cross-flow trays with segmental straight or sloped downcomers are considered.

- The column inside dimeter is calculated based on the input fraction of the flooding vapor velocity and the

downcomer to tray area fraction.

- Leaving blank the Tray diameter dialogue box, the program will estimate the appropriate inside diameter

rounded to the above 0.5 ft based on semiempirical and hydraulic correlations. Inserting the desired value, the other

calculations will be perform with this input value.

- Fair, Kister & Haas and Smith

correlations are available for the flood correlations.

- Common industrial values can be selected in combo boxes for the Tray

spacing and Tray deck thickness.

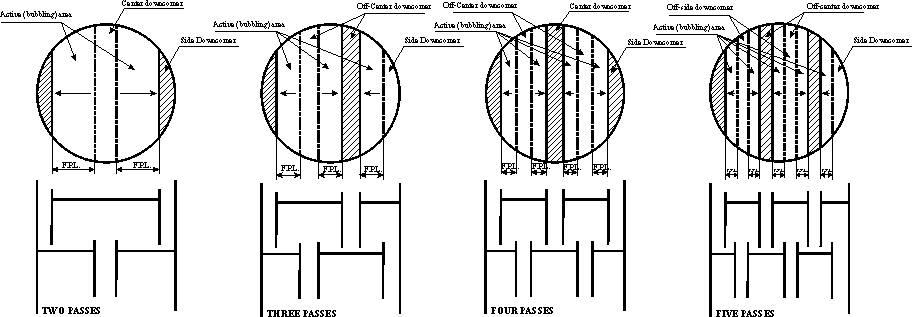

- 1 to 5 No of liquid passes can be selected on the cross section of the tray to establish the tray layout.

- The System factor is an empirical parameter which takes into account the foaming tendency of the liquid system.

The value of 1 is taken for non-foaming liquids.

- If values are available for the Top inside space above the first

tray or Bottom inside space below the last tray,

they can be filled in the appropriate dilogue boxes. Leaving them blank, a default 15% supplementary

void space with a top to bottom height ratio of 2/3 will be assumed by default.

- A click on the Evaluate Diameter & Height button will

display in the Sizing Results frame the main sizing and hydraulic

parameters for the maximum vapor loaded tray inside the column.

- A click on the Evaluate and Export All button will display all the calculated values for each tray inside the column in a text file.

The file can be saved or exported in other applications with Select, Copy and Paste options.

- The Sizing section is recommended to be studied after the operating condition of the column have been established.

The Sizing section uses the results obtained after the run of the column, but it can be seen as an independent option.

|

- The tray layout drawings explain the significance of the parameters used in this section.

The flow path length and different areas are detailed for 1 to 5 liquid passes across the tray.

|

|

|

|

- The Distillation_Column equipment simulates the separation of volatile

component that takes place in a single distillation column.

- The Boiling Point (Wang & Henke) multi-stage multi-component rigorous

algoritm is implemented.

- The required input data are at least 1 and up to 4 feed streams (numbered

from top to bottom) containing volatile solvent mixtures, the number of actual stages

inside the column, the liquid reflux ratio returned from the condenser to the first

stage inside the column and the distillate rate, expressed in kg-moles/hr to be

extracted as top product.

- Up to 2 optional side extractions can be connected to the equipment.

- The total number of stages should be specified in the Input Data tab.

In the Side Streams tab each feed needs to be assigned to a stage number. Two feeds

cannot be assigned to the same stage. The side extraction stages, flow rates in

kg-moles/hr and the phase from which each stream is extracted should be specified

in the Side Stream tab.

- The Input Data grid contains the first guess values for the column

solver algoritm for pressure, Murphree efficiency, temperature, liquid and vapor

flows (in kg-mole/hr) on each tray inside the column. These values can be modified on each stage. An Automation frame helps the user to fill the

same value on each stage by selecting the desired parameter in

the Fill Grid Column combo box, inserting the value in the cell below and giving

a click on the Refresh button

- Based on the Coolant Out Temperature, Heating Out Temperature and

Heat Losses fraction from the Input data tab, the Steam Per Feed, Condenser and

Reboiler Duties and Heat Losses are calculated and displayed in the Reports tab.

The actual Reflux Rate is calculated and displayed in the Reports tab. The results

are expressed in the units of the case model.

- The calculated parameters are displayed in the

report grid for each stage. A click on the Export to .txt file will display the

column profile in a text file displayed on the screen.

- A 2D or 3D chart will display the column profile for the following

parameters: Temperature, Pressure,Total loading, Liquid and Vapor loadings based

on the selection made in the combo box from the Chart tab. The Temperature parameter

is selected by default.

- A separate sizing module will optionally calculate the diameter and

height of the column, together with hydraulic and tray layout parameter. Sieve, Valve or Bubble cap trays can be selected, Fair, Kister &

Haas or Smith flodding correlation are available and straight or sloped downcomers

can be performed.

- Leaving blank the Tray diameter cell will calculate

this value based

on the Flood fraction, Flood correlation and Downcomer Area to Tray Area ratio input

values. Otherwise the input value will be used to calculate

the other parameters on each tray. Leaving blank both the Top and the Bottom Column

heights zones will calculate these values based on a 15% volume supplement for the zones above the upper

tray and below the lowest tray in the column. The top to bottom

height default ratio of 2/3 is considered.

- After the convergence of the equipment the Sizing tab will perform

the calculation by using either the Evaluate Diameter & Height button or the

Evaluate & Export All button. In the first case the diameter will be calculated

considering the maximum vapor loaded tray inside the column. In the second case,

all the trays will be separately calculated and the results will be exported in

a text file displayed on the screen.

- A number of helpful warning messages regarding good engineering practice

or exceeding of the sizing correlation limits are displayed specifically for each

tray either in the Run output window or at the bottom of each tray sizing calculation

in the exprted file

- The bottom recirculation flow temperature is the saturated vapor temperature for

the bottom product mixture.

- If are not specified, the cold and the hot utility are used by default:

coolant - water at 77 °F

heating medium - steam at 212 °F

pressure - 0 psig

- Heat duty taken by the condenser is calculated as:

Qcond = (Toph - Dh) * (D + R)

where:

Qcond is the heat duty taken by the condenser

Toph is the enthalpy of the top stream

(inlet hot stream in condenser)

Dh is the distillate enthalpy

D is the distillate flow

R is the reflux flow

R = Rr * D

where:

Rr is the reflux ratio, specified by user

C =Qcond / (Coh - Cih)

where:

C is the coolant flow

Coh is the coolant outlet enthalpy

Cih is the coolant inlet enthalpy

- Minimum heat duty required for reboiler (in case that the heat loss is zero) is

calculated as:

Qrebmin = D * Dh + B * Bh + Qcond - Sum (Fi * Fhi

)

where:

Qrebmin is the minimum heat duty required forreboiler

Dh is the distillate enthalpy

B is the bottom product stream flow

Bh is the bottom product stream enthalpy

Fi is the feed stream flow

Fhi is the feed stream enthalpy

- Real heat duty for reboiler is:

Qreb = Qrebmin * (1+HL)

where:

Qreb is the real heat duty for reboiler

HL is the heat loss fraction in the column

S = Qreb / (Sih - Soh)

where:

S is the steam flow required

Sih is the stem inlet enthalpy

Soh is the steam outlet enthalpy

- The necessary of steam per 100 mass units of feed is calculated as:

SPF = 100 * S / F

where:

SPF is the steam per feed

Coolant outlet temperature higher than the hot stream temperature in condenser!

Coolant outlet temperature higher than the hot stream temperature in condenser!

Solution: decrease the temperature for the coolant outlet.

Coolant inlet temperature higher than the distillate temperature!

Coolant inlet temperature higher than the distillate temperature!

Solution: decrease the temperature of coolant inlet.

Specified coolant outlet temperature lower or equal than the coolant inlet temperature!

Specified coolant outlet temperature lower or equal than the coolant inlet temperature!

Solution: increase the coolant outlet temperature.

Coolant outlet temperature higher than the distillate temperature!

Coolant outlet temperature higher than the distillate temperature!

Solution: decrease the temperature of coolant outlet.

Steam inlet temperature lower than the bottom product temperature!

Steam inlet temperature lower than the bottom product temperature!

Solution: increase the steam inlet temperature.

Condensate outlet temperature higher or equal than inlet steam temperature!

Condensate outlet temperature higher or equal than inlet steam temperature!

Solution: decrease the condensate outlet temperature.

Condensate outlet temperature higher than the condensing temperature. Steam in condensate!

Condensate outlet temperature higher than the condensing temperature. Steam in condensate!

Solution: decrease the condensate outlet temperature.

Condensate outlet temperature lower than the bottom temperature!

Condensate outlet temperature lower than the bottom temperature!

Solution: increase the condensate outlet temperature.

Condensate outlet temperature higher than the inlet steam temperature!

Condensate outlet temperature higher than the inlet steam temperature!

Solution: increase the intlet steam temperature.

Pressure drop in reboiler higher than the inlet steam pressure!

Pressure drop in reboiler higher than the inlet steam pressure!

Solution: increase the inlet steam pressure or lower the pressure drop in the reboiler.

* The Total_Column_Height exceeds the maximum recommended safety height of 175 ft. Rare values are up to 190...212 ft).

* The Total_Column_Height exceeds the maximum recommended safety height of 175 ft. Rare values are up to 190...212 ft).

Solution: lower the number of trays, split the column into two columns or lower the Tray spacing.

* The Fair's Flooding Factor is outside the original correlation limits because : FLV Sherwood No < 0. Impossible situation.

* The Fair's Flooding Factor is outside the original correlation limits because : FLV Sherwood No < 0. Impossible situation.

Solution: change the inputs.

* The Fair's Flooding Factor is outside the original correlation limits because: FLV Sherwood No < 0.01. Extrapolation will be used.

* The Fair's Flooding Factor is outside the original correlation limits because: FLV Sherwood No < 0.01. Extrapolation will be used.

Solution: accept this or change the inputs.

* The Fair's Flooding Factor is outside the original correlation's limits because: Tray_Spacing is outside the range [6..36] in. Extrapolation will be used.

* The Fair's Flooding Factor is outside the original correlation's limits because: Tray_Spacing is outside the range [6..36] in. Extrapolation will be used.

Solution: accept this or change the Tray spacing.

* The Smith's Flooding Factor is outside the original correlation limits because: FLV Sherwood No < 0. Impossible situation.

* The Smith's Flooding Factor is outside the original correlation limits because: FLV Sherwood No < 0. Impossible situation.

Solution: change the inputs.

* The Smith's Flooding Factor is outside the original correlation's limits because: FLV Sherwood No < 0.02. Extrapolation will be used.

* The Smith's Flooding Factor is outside the original correlation's limits because: FLV Sherwood No < 0.02. Extrapolation will be used.

Solution: accept this or change the inputs.

* The Smith's Flooding Factor is outside the original correlation's limits because: FLV Sherwood No > 1. Extrapolation will be used.

* The Smith's Flooding Factor is outside the original correlation's limits because: FLV Sherwood No > 1. Extrapolation will be used.

Solution: accept this or change the inputs.

The Smith's Flooding Factor is outside the original correlation's limits because: The Settling_Height (Tray_Spacing - hw - how) is outside [2..30] in. Extrapolation will be used.

The Smith's Flooding Factor is outside the original correlation's limits because: The Settling_Height (Tray_Spacing - hw - how) is outside [2..30] in. Extrapolation will be used.

Solution: accept this or lower the Tray spacing.

* Froth_Relative_Density abscisa: (uA*(RhoV^0.5)) is out of the range [0..2.5]. Extrapolation will be used.

* Froth_Relative_Density abscisa: (uA*(RhoV^0.5)) is out of the range [0..2.5]. Extrapolation will be used.

Solution: accept this or change the inputs.

* The calculated Froth_Relative_Density is outside of the range [0..1].

* The calculated Froth_Relative_Density is outside of the range [0..1].

Solution: change the inputs.

* Aeration_Factor abscisa: (uA*(Rhov^0.5))is out of range [0..2.5].Extrapolation will be used.

* Aeration_Factor abscisa: (uA*(Rhov^0.5))is out of range [0..2.5].Extrapolation will be used.

Solution: accept this or change the inputs.

* Aeration_Factor is out of range [0..1].

* Aeration_Factor is out of range [0..1].

Solution: change the inputs.

* The Weir_Constriction_Correction_Factor FW (Bolles) is outside the recomended range limits because:

Weir_Length-to-Column_Cross_Section_Diameter ratio (Lw/Dc) < 0.5. Extrapolation will be used.

* The Weir_Constriction_Correction_Factor FW (Bolles) is outside the recomended range limits because:

Weir_Length-to-Column_Cross_Section_Diameter ratio (Lw/Dc) < 0.5. Extrapolation will be used.

Solution: accept this or change the inputs.

* The Weir_Constriction_Correction_Factor FW (Bolles) is outside the recomended range limits because:

Weir_Length-to-Column_Cross_Section_Diameter ratio (Lw/Dc) > 1. Impossible case. Value is set to zero.

* The Weir_Constriction_Correction_Factor FW (Bolles) is outside the recomended range limits because:

Weir_Length-to-Column_Cross_Section_Diameter ratio (Lw/Dc) > 1. Impossible case. Value is set to zero.

Solution: change the inputs.

* The Weir_Constriction_Correction_Factor FW (Bolles) exceeds the recomended limit. Extrapolation will be used.

* The Weir_Constriction_Correction_Factor FW (Bolles) exceeds the recomended limit. Extrapolation will be used.

Solution: accept this or change the inputs.

* The FAIR's_Fractional_Entrainment Correlation is outside the recomended range limits because: Flood_Percent < 30%. Extrapolation will be used.

* The FAIR's_Fractional_Entrainment Correlation is outside the recomended range limits because: Flood_Percent < 30%. Extrapolation will be used.

Solution: accept this or change the inputs.

* Flood_Percent > 100%. Flodding regime. Vapor velocity exceeds the estimated flodding velocity. Extrapolation will be used to evaluate the weeping effect.

* Flood_Percent > 100%. Flodding regime. Vapor velocity exceeds the estimated flodding velocity. Extrapolation will be used to evaluate the weeping effect.

Solution: change the inputs.

* Negative pressure drop through tne perforations. Value is set to zero.

* Negative pressure drop through tne perforations. Value is set to zero.

Solution: change the inputs.

The abscisa: Weir_Height + Liquid_Height_Over_the_Weir exceeds the experimental chart range of 4 in. Extrapolated values will be used.

The abscisa: Weir_Height + Liquid_Height_Over_the_Weir exceeds the experimental chart range of 4 in. Extrapolated values will be used.

Solution: change Weir hight.

* The Fractional_Hole_Area Af=Ah/Aa is below the experimental chart correlation. Extrapolated values will be used to evaluate the weeping effect.

* The Fractional_Hole_Area Af=Ah/Aa is below the experimental chart correlation. Extrapolated values will be used to evaluate the weeping effect.

Solution: accept this or change the Hole area to Active area ratio.

* The Fractional_Hole_Area Af=Ah/Aa is above the experimental chart correlation. Extrapolated values will be used to evaluate the weeping effect.

* The Fractional_Hole_Area Af=Ah/Aa is above the experimental chart correlation. Extrapolated values will be used to evaluate the weeping effect.

Solution: accept this or change the Hole area to Active area ratio.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to:FLV Sherwood No < 0. Impossible situation.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to:FLV Sherwood No < 0. Impossible situation.

Solution: change the inputs.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: FLV Sherwood No < 0.001. Extrapolation will be used.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: FLV Sherwood No < 0.001. Extrapolation will be used.

Solution: accept this or change the inputs.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: FLV Sherwood No > 10. Extrapolation will be used.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: FLV Sherwood No > 10. Extrapolation will be used.

Solution: accept this or change the inputs.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: Weir_Hegiht < 1/8 = 0.125 in. Extrapolation will be used.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: Weir_Hegiht < 1/8 = 0.125 in. Extrapolation will be used.

Solution: accept this or change the Weir height.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: Weir_Height > 5 in. Extrapolation will be used.

* The Chan and Price Dump_Factor is outside the original correlation's limits due to: Weir_Height > 5 in. Extrapolation will be used.

Solution: accept this or change the Weir height.

* Tray_Spacing is below 24 in. There is inadequate space for manway access on the tray.

* Tray_Spacing is below 24 in. There is inadequate space for manway access on the tray.

Solution: accept this or change the Tray spacing.

* Open(Hole)_Area_Fraction is ouside the recommended range [0.04..0.16]. For Sieve Trays the recommended range is [0.05..0.15], commonly 0.1.

* Open(Hole)_Area_Fraction is ouside the recommended range [0.04..0.16]. For Sieve Trays the recommended range is [0.05..0.15], commonly 0.1.

Solution: change the Open(Hole) area fraction.

* The Downcomer_Clearence(Seal) should never be under 1/2 in (12.7 mm). Usual Values are {1.5, 1.75, 2, 2.25, 2.5} inches.

* The Downcomer_Clearence(Seal) should never be under 1/2 in (12.7 mm). Usual Values are {1.5, 1.75, 2, 2.25, 2.5} inches.

Solution: change the Downcomer clearence.

* Tray_Deck_Thikness/Hole_Diameter ratio for sieve tray is outside of the recommended range [0.4..0.7].

* Tray_Deck_Thikness/Hole_Diameter ratio for sieve tray is outside of the recommended range [0.4..0.7].

Solution: change the Tray thikness or the Hole diameter.

* The Hole_Pitch/Hole_Diameter ratio for sieve trays is outside the recommended range [2..4.5], with optimum around 3.8 in.

* The Hole_Pitch/Hole_Diameter ratio for sieve trays is outside the recommended range [2..4.5], with optimum around 3.8 in.

Solution: change the Hole_Pitch.

* The Weir_Height should be less than (0.15*Tray_Spacing).The Weir_Height range is [1..4] in and 2..3 in are commonly used.

* The Weir_Height should be less than (0.15*Tray_Spacing).The Weir_Height range is [1..4] in and 2..3 in are commonly used.

Solution: change the Tray spacing or the Weir height.

* The Weir_Height is recommended to exceed the Downcomer_Clearence with at least 1/2 in (12.7 mm).

The Weir_Height range is [1..4] in and 2..3 in are commonly used.

* The Weir_Height is recommended to exceed the Downcomer_Clearence with at least 1/2 in (12.7 mm).

The Weir_Height range is [1..4] in and 2..3 in are commonly used.

Solution: change the Weir height or the Downcomer clearence.You may use an inlet weir or a recessed seal pan to ensure a positive downcomer seal.

* The Top-to-Bottom Sloped_Downcomer_Area ratio is outside the recommended range [1.5..2].

* The Top-to-Bottom Sloped_Downcomer_Area ratio is outside the recommended range [1.5..2].

Solution: change the Top-to-Bottom Sloped downcomer area ratio.

* The abscisa (Liquid_Density-Vapor_Density) is outside the Nutter and Koch correlation chart range [10..75] lbs/ft3.

* The abscisa (Liquid_Density-Vapor_Density) is outside the Nutter and Koch correlation chart range [10..75] lbs/ft3.

Solution: check the inputs.

* Downcomer_Area smaller than (0.05..0.08)*Tower_Cross_Section_Area should be avoided. The recommended range is [0.1...0.2]*Tower_Cross_Section_Area.

* Downcomer_Area smaller than (0.05..0.08)*Tower_Cross_Section_Area should be avoided. The recommended range is [0.1...0.2]*Tower_Cross_Section_Area.

Solution: change the Downcomer area to Tray area ratio or the Tray diameter.

* Sloped_Downcomers are not used below 16 in (0.4064 mt) Tray_Spacing. Straight downcomer is recommended to be used.

* Sloped_Downcomers are not used below 16 in (0.4064 mt) Tray_Spacing. Straight downcomer is recommended to be used.

Solution: change the Tray spacing or select No for Sloped Downcomer.

* The Flow_Path_Length is less then the design limit of 16 in (406.4 mm).It should exceed 16...18 in. There is inadequate space for manway access on the tray.

* The Flow_Path_Length is less then the design limit of 16 in (406.4 mm).It should exceed 16...18 in. There is inadequate space for manway access on the tray.

Solution: change the inputs.

* The Flow_Path_Length should not exceed (0.64*Column_Diameter) in (good practice guideline).

* The Flow_Path_Length should not exceed (0.64*Column_Diameter) in (good practice guideline).

Solution: change the inputs.

* The Top_Weir_Length should not be lower than 55% of the Column_Diameter. Tray efficiency might be affected.

* The Top_Weir_Length should not be lower than 55% of the Column_Diameter. Tray efficiency might be affected.

Solution: change the Weir length or the Tray diameter.

* The Top Weir Length-to-Column_Internal_Diameter percent is recommended to be arround 75%, as a common practice.

* The Top Weir Length-to-Column_Internal_Diameter percent is recommended to be arround 75%, as a common practice.

Solution: accept the value or change the Weir length or the Tray diameter.

* The total Top downcomer outlet Weir_Load QL is outside the good practice guideline range [7..13] gpm/in_outlet_weir.

Some authors recommend QL values below 8 for sieve trays.

* The total Top downcomer outlet Weir_Load QL is outside the good practice guideline range [7..13] gpm/in_outlet_weir.

Some authors recommend QL values below 8 for sieve trays.

Solution: increase the No of passes if the upper limit is exceeded. Change the inputs if the lower limit is exceeded.

* The total Bottom downcomer outlet Weir_Load QL is outside the good practice guideline range [7..13] gpm/in_outlet_weir.

* The total Bottom downcomer outlet Weir_Load QL is outside the good practice guideline range [7..13] gpm/in_outlet_weir.

Solution: increase the No of passes if the upper limit is exceeded. Change the inputs if the lower limit is exceeded.

* The Flow_Path_Length Center-to-Side is less then the design limit of 16 in (406.4 mm). It should exceed 16...18 in. There is inadequate space for manway access on the tray.

* The Flow_Path_Length Center-to-Side is less then the design limit of 16 in (406.4 mm). It should exceed 16...18 in. There is inadequate space for manway access on the tray.

Solution: change the inputs.

* The Flow_Path_Length Center-to-Side should not exceed (0.64*Column_Diameter)(good engineering guideline).

* The Flow_Path_Length Center-to-Side should not exceed (0.64*Column_Diameter)(good engineering guideline).

Solution: change the inputs.

* The Side Top_Weir_Length should not be lower than 55% of the Column_Diameter . Tray efficiency might be affected.

* The Side Top_Weir_Length should not be lower than 55% of the Column_Diameter . Tray efficiency might be affected.

Solution: change the inputs.

* The Center Top_Weir_Length should not be lower than 55% of the Column_Diameter. Tray efficiency might be affected.

* The Center Top_Weir_Length should not be lower than 55% of the Column_Diameter. Tray efficiency might be affected.

Solution: change the inputs.

* The Side Top downcomer outlet Weir_Load QL is outside the good practice guideline range [7..13] gpm/in_outlet_weir.

* The Side Top downcomer outlet Weir_Load QL is outside the good practice guideline range [7..13] gpm/in_outlet_weir.

Solution: increase the No of passes if the upper limit is exceeded. Change the inputs if the lower limit is exceeded.

* Total_Tray_Pressure_Drop is ouside the good practice recommendation [3..5] in of liqid; [0.08..0.12] psi.

* Total_Tray_Pressure_Drop is ouside the good practice recommendation [3..5] in of liqid; [0.08..0.12] psi.

Solution: change the Fractional_Hole_Area (Open_Area), if Dry_Pressure_Drop dominates or the Weir height, if the Wet_Pressure_Drop dominates.

* Downcomer_Seal might fail. The Clear_Liquid_Height in the Downcomer does not exceed the Downcomer_clearence with at least than 2 inches.

* Downcomer_Seal might fail. The Clear_Liquid_Height in the Downcomer does not exceed the Downcomer_clearence with at least than 2 inches.

Solution: change the Downcomer clearence or the Tray spacing.

* The Froth_in_Downcomer exceeds the safety limit and may reach the upper tray.

* The Froth_in_Downcomer exceeds the safety limit and may reach the upper tray.

Solution: increase of Downcomer clearence and/or the Tray spacing.

* Risk of choke in the downcomer: Downcomer percent of Choke (Koch correlation) > 90%.

* Risk of choke in the downcomer: Downcomer percent of Choke (Koch correlation) > 90%.

Solution: change the inputs.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 3 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 3 s.

Solution: change the inputs.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 4 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 4 s.

Solution: change the inputs.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 5 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 5 s.

Solution: change the inputs.

* The FLOOD_Fair percent is below the recommended range [30..80]%.

* The FLOOD_Fair percent is below the recommended range [30..80]%.

Solution: change the inputs.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Fair Correlation > 80%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Fair Correlation > 80%.

Solution: change the inputs.

* The FLOOD_Percent Kister & Haas Correlation is below the recommended range [30..80]%.

* The FLOOD_Percent Kister & Haas Correlation is below the recommended range [30..80]%.

Solution: change the inputs.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Kister & Haas Correlation > 80%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Kister & Haas Correlation > 80%.

Solution: change the inputs.

* The FLOOD_Smith percent is below the recommended range [30..80]%.

* The FLOOD_Smith percent is below the recommended range [30..80]%.

Solution: change the inputs.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Smith Correlation > 80%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Smith Correlation > 80%.

Solution: change the inputs.

* Weeping might occur. Weep_Point_Vapor_Load_Percent < 100 %.

* Weeping might occur. Weep_Point_Vapor_Load_Percent < 100 %.

Solution: change the inputs.

* Dumping_Point is reached. Dump_Percent < 100%. All the liquid is weeping through the tray.

* Dumping_Point is reached. Dump_Percent < 100%. All the liquid is weeping through the tray.

Solution: change the inputs to raise the Vapor Velocity.

* Weeping is significant. The Weep_Fraction > 0.1, the maximum tolerable value.

* Weeping is significant. The Weep_Fraction > 0.1, the maximum tolerable value.

Solution: change the inputs.

* The Weir_Height is outside the recommended limits [2...4] in or [(2 - how - 0.5 * hhg), (42 - how - 0.5 * hhg)].

* The Weir_Height is outside the recommended limits [2...4] in or [(2 - how - 0.5 * hhg), (42 - how - 0.5 * hhg)].

Solution: change the input Weir height.

* The Column_Heigt-to-Diameter ratio is outside the optimum range of [20..30].

* The Column_Heigt-to-Diameter ratio is outside the optimum range of [20..30].

Solution: change the inputs.

Missing utilities stream(s)!

Missing utilities stream(s)!

Solution: check if all the utilities streams are connected to the equipment.

apiMAX full license required!

apiMAX full license required!

Solution: install the Professional edition license for apiMAX.

Calculations cannot be performed!

Calculations cannot be performed!

Solution: please check the inputs.

No feed connected!

No feed connected!

Solution: check if at least one feed stream is connected to the equipment.

No distillate or bottom stream connected!

No distillate or bottom stream connected!

Solution: check if the distillate stream is connected to the equipment.

Empty feed flow!

Empty feed flow!

Solution: check the feed flow(s) not to be empty.

(Colapse/Expand Data Description)

(Colapse/Expand Data Description)

(Colapse/Expand Equipment Properties)

(Colapse/Expand Equipment Properties)

Warnings

Warnings  Coolant outlet temperature higher than the hot stream temperature in condenser!

Coolant outlet temperature higher than the hot stream temperature in condenser!

Coolant inlet temperature higher than the distillate temperature!

Coolant inlet temperature higher than the distillate temperature!

Specified coolant outlet temperature lower or equal than the coolant inlet temperature!

Specified coolant outlet temperature lower or equal than the coolant inlet temperature!

Coolant outlet temperature higher than the distillate temperature!

Coolant outlet temperature higher than the distillate temperature!

Steam inlet temperature lower than the bottom product temperature!

Steam inlet temperature lower than the bottom product temperature!

Condensate outlet temperature higher or equal than inlet steam temperature!

Condensate outlet temperature higher or equal than inlet steam temperature!

Condensate outlet temperature higher than the condensing temperature. Steam in condensate!

Condensate outlet temperature higher than the condensing temperature. Steam in condensate!

Condensate outlet temperature lower than the bottom temperature!

Condensate outlet temperature lower than the bottom temperature!

Condensate outlet temperature higher than the inlet steam temperature!

Condensate outlet temperature higher than the inlet steam temperature!

Pressure drop in reboiler higher than the inlet steam pressure!

Pressure drop in reboiler higher than the inlet steam pressure!

* The calculated Froth_Relative_Density is outside of the range [0..1].

* The calculated Froth_Relative_Density is outside of the range [0..1].

* Aeration_Factor abscisa: (uA*(Rhov^0.5))is out of range [0..2.5].Extrapolation will be used.

* Aeration_Factor abscisa: (uA*(Rhov^0.5))is out of range [0..2.5].Extrapolation will be used.

* Aeration_Factor is out of range [0..1].

* Aeration_Factor is out of range [0..1].

* Negative pressure drop through tne perforations. Value is set to zero.

* Negative pressure drop through tne perforations. Value is set to zero.

* Tray_Spacing is below 24 in. There is inadequate space for manway access on the tray.

* Tray_Spacing is below 24 in. There is inadequate space for manway access on the tray.

* The Top-to-Bottom Sloped_Downcomer_Area ratio is outside the recommended range [1.5..2].

* The Top-to-Bottom Sloped_Downcomer_Area ratio is outside the recommended range [1.5..2].

* The Flow_Path_Length should not exceed (0.64*Column_Diameter) in (good practice guideline).

* The Flow_Path_Length should not exceed (0.64*Column_Diameter) in (good practice guideline).

* The Froth_in_Downcomer exceeds the safety limit and may reach the upper tray.

* The Froth_in_Downcomer exceeds the safety limit and may reach the upper tray.

* Risk of choke in the downcomer: Downcomer percent of Choke (Koch correlation) > 90%.

* Risk of choke in the downcomer: Downcomer percent of Choke (Koch correlation) > 90%.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 3 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 3 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 4 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 4 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 5 s.

* The Apparent_Residende_Time is lower than the Minimum_Recommended_Residence Time = 5 s.

* The FLOOD_Fair percent is below the recommended range [30..80]%.

* The FLOOD_Fair percent is below the recommended range [30..80]%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Fair Correlation > 80%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Fair Correlation > 80%.

* The FLOOD_Percent Kister & Haas Correlation is below the recommended range [30..80]%.

* The FLOOD_Percent Kister & Haas Correlation is below the recommended range [30..80]%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Kister & Haas Correlation > 80%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Kister & Haas Correlation > 80%.

* The FLOOD_Smith percent is below the recommended range [30..80]%.

* The FLOOD_Smith percent is below the recommended range [30..80]%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Smith Correlation > 80%.

* Possible Entrainment_(Jet)_Flooding: FLOOD_Smith Correlation > 80%.

* Weeping might occur. Weep_Point_Vapor_Load_Percent < 100 %.

* Weeping might occur. Weep_Point_Vapor_Load_Percent < 100 %.

* Dumping_Point is reached. Dump_Percent < 100%. All the liquid is weeping through the tray.

* Dumping_Point is reached. Dump_Percent < 100%. All the liquid is weeping through the tray.

* Weeping is significant. The Weep_Fraction > 0.1, the maximum tolerable value.

* Weeping is significant. The Weep_Fraction > 0.1, the maximum tolerable value.

* The Column_Heigt-to-Diameter ratio is outside the optimum range of [20..30].

* The Column_Heigt-to-Diameter ratio is outside the optimum range of [20..30].

Errors

Errors  Calculations cannot be performed!

Calculations cannot be performed!