What do you want to see?

|

|

Data Description

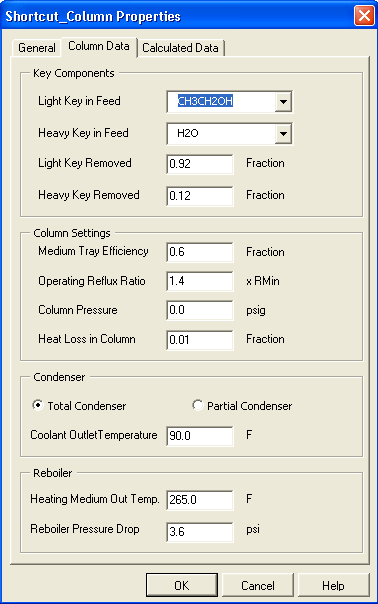

| Data | Unit | Description | ||

| Set | Item | Type | Native | |

| Equipment Properties | Light Key in Feed | String | Combo box which lets the user to choose the light key in the inlet mixture. Light key is the most volatile (e.g. ethanol), while heavy key is the less volatile (e.g. water). | |

| Heavy Key in Feed | String | Combo box which lets the user to choose the heavy key in the inlet mixture. | ||

| Light Key Removed | Fraction or Percent | Fraction | The light key mass fraction of the feed light key, removed in the top product. | |

| Heavy Key Removed | Fraction or Percent | Fraction | The heavy key mass fraction of the feed heavy key, removed in the top product. | |

| Medium Tray Efficiency | Fraction or Percent | Fraction | The medium efficiency of the trays. used in calculation of real trays no . | |

| Reflux Ratio | Fraction or Percent | Fraction | Fraction to determinate the top recirculation flow as multiplication factor of the minimum reflux ratio calculated. | |

| Column Pressure | Pressure | psia | The pressure in column also is the pressure for the outlet streams (distillate and bottom product). | |

| Heat Loss in Column | Fraction or Percent | Fraction | The total heat loss of the column, fraction of the reboiler heat duty. | |

| Condenser Type | Boolean | Total Condenser or Partial Condenser | ||

| Coolant Outlet Temperature | Temperature | F | The outlet temperature for the cooling medium in the top. | |

| Heating Medium Out Temp | Temperature | F | The outlet temperature for the heating medium (bottom). | |

| Reboiler Pressure Drop | Pressure | psia | The pressure drop in reboiler on the heating medium side (usually steam pressure drop). | |

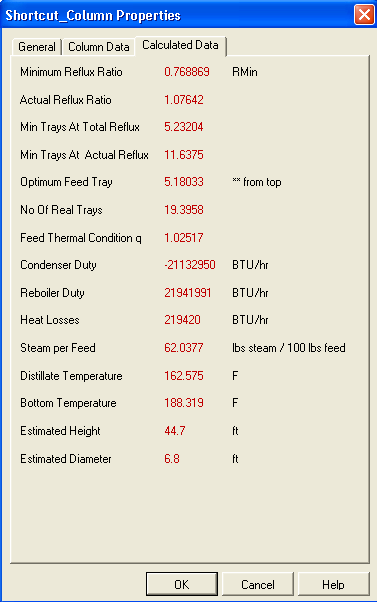

| Output Data | Minimum Reflux Ratio | The minimum reflux ratio, determined from minimum recirculation flow on the top. | ||

| Actual Reflux Ratio | The actual recirculation flow on the top ratio, multiplication of the minimum reflux ratio. | |||

| Minimum Number of Trays at Total Reflux | The number of ideal stages, calculated at total reflux. | |||

| Minimum Number of Trays at Actual Reflux | The number of ideal stages, calculated considering the actual reflux ratio. | |||

| Feed Tray | Optimum feed plate location, counted from the top. | |||

| Number of Real Trays | The number of real plates calculated using the specified medium tray efficiency. | |||

| Feed q | The thermal condition of the feed flow. | |||

| Condenser Duty | Energy Flow | BTU/hr | The condenser heat that is removed by the coolant. | |

| Reboiler Duty | Energy Flow | BTU/hr | The reboiler heat that is supplied by the heating medium (steam). | |

| Heat Losses | Energy Flow | BTU/hr | The heat losses of the column (the units will be the energy flow units, e.g. GJ/h). | |

| Steam Per Feed | The steam amount used for 100 mass units of feed. | |||

| Distillate Temperature | Temperature | F | The outlet temperature of the distillate stream. | |

| Bottom Temperature | Temperature | F | The outlet temperature of the bottom stream. | |

| Height | Length | ft | The estimated height of the column. | |

| Diameter | length | ft | The estimated diameter of the column. | |

Equipment Properties

|

|

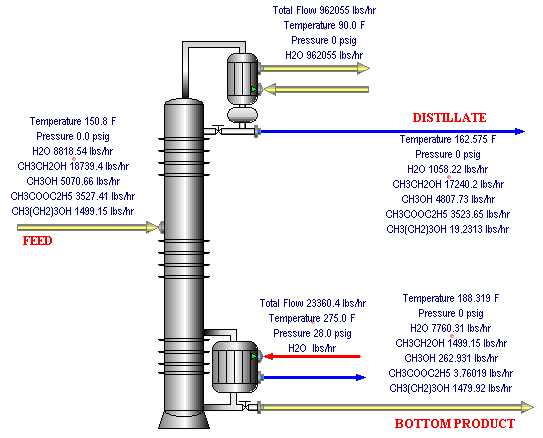

Example of using equipment

|

Method&Equations

Objective of any distillation process is to recover pure products. In case of multicomponent mixtures we may be interested in one, two or more components. Unlike in binary distillation, fixing molefraction of one of the components in a product does not fix the mole fraction of other components .On the other hand fixing compositions of all the components in the distillate and the bottoms product, makes almost impossible to meet specifications exactly.

FUG (Fenske-Underwood-Gilliland) algorithm is a widely used shortcut method.

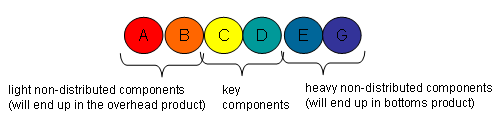

First step is to establish if the separation is sharp or no. This will decide if the non-key components (if multicomponent mixture is involved) are distributed or undistributed. Components with negligible concentration in one of the products are called undistributed.

The components are arranged by their relative volatility refered (usually) to the heavy key component selected. If the key components are adjacents and the relative volatility of the other components are sensible different, the separation is a sharp one.

The FUG shortcut method assumes constant relative volatility and constant molar overflow.

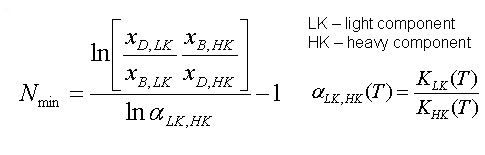

The number of minimum ideal stages at total reflux is calculated using the Fenske equation:

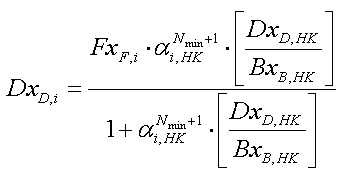

The distribution of the non key components is evaluated using the equation:

A trial end error algorithm is used till the distribution of the non key components does not change significantly between two iterations of Nmin calculation.

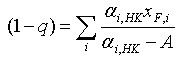

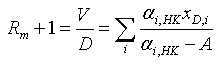

The minimum reflux ratio is calculated in two steps, considering the Underwood I and Underwood II equations:

.

q is the thermal feed condition.

For a given q, and the feed composition we are looking for A satisfies this equation (usually A is between a LK and a HK) .

Once A is found, the minimum reflux ratio is calculated:

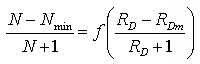

The number of ideal stages at actual reflux is calculated using the Gilliland correlation:

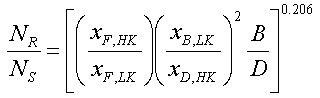

Kirkbride equation calculates the optimum feed stage location, as division between the number of ideal plates required in the rectification zone and the number of ideal plates required for stripping:

Where B is the molar flow of the bottom product and D is the molar flow od the distillate stream.

The dimensions of the column (height and diameter) are estimated using the following correlations:

![]()

Where NT is the number of real trays calculated uing the specified medium efficiency.

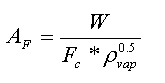

The diameter is computed from the geometry of the column area, assuming the free area required is 90% of total column area. The free area is calculated using the equation:

Where : Fc is the column factor assuming normal pressure distillation and 18" standard tray spacing (here equal to 1.55)

Rho vap is the vapor density in the top of the column (in lbs/ft3)

W is the vapor flow (in lbs/s)

Warnings

Warnings

Not

enough heavy key components in the inlet stream!

Not

enough heavy key components in the inlet stream!

Coolant outlet temperature higher than the hot stream temperature in condenser!

Coolant outlet temperature higher than the hot stream temperature in condenser!

Coolant inlet temperature higher than the distillate temperature!

Coolant inlet temperature higher than the distillate temperature!

Specified coolant outlet temperature lower or equal than the coolant inlet temperature!

Specified coolant outlet temperature lower or equal than the coolant inlet temperature!

Coolant outlet temperature higher than the distillate temperature!

Coolant outlet temperature higher than the distillate temperature!

Steam inlet temperature lower than the bottom product temperature!

Steam inlet temperature lower than the bottom product temperature!

Condensate outlet temperature higher or equal than inlet steam temperature!

Condensate outlet temperature higher or equal than inlet steam temperature!

Condensate outlet temperature higher than the condensing temperature. Steam in condensate!

Condensate outlet temperature higher than the condensing temperature. Steam in condensate!

Condensate outlet temperature lower than the bottom temperature!

Condensate outlet temperature lower than the bottom temperature!

Error in alfa calculation! The results may not be reliable!

Error in alfa calculation! The results may not be reliable!

Error in convergence for Rmin calculation!

Error in convergence for Rmin calculation!

Wrong tray efficiency! Value x.x will be used!

Wrong tray efficiency! Value x.x will be used!

Pressure drop in reboiler higher than the inlet steam pressure!

Pressure drop in reboiler higher than the inlet steam pressure!

Errors

Errors

No light key component or heavy key component in the inlet stream!

No light key component or heavy key component in the inlet stream!

Wrong key component selection! No key component selected!

Wrong key component selection! No key component selected!

Wrong key component selection! The key components are the same!

Wrong key component selection! The key components are the same!

Critical error during calculations! Calculation aborted!

Critical error during calculations! Calculation aborted!