|

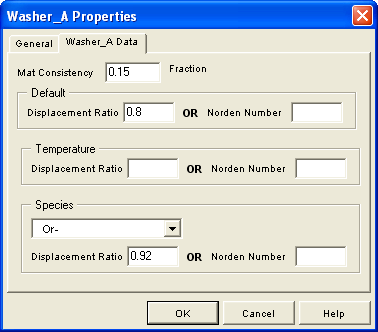

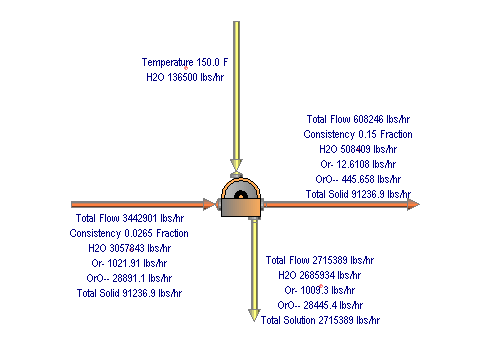

Washer A is used to wash a pulp stream and to remove with different displacement ratio some components.

|

What do you want to see?

|

|

Data Description

|

Data |

Unit |

Description |

|

Set |

Item |

Type |

Native |

|

Equipment Properties |

Mat Consistency |

Fraction or percentage |

fraction |

Consistency of the outlet pulp stream. |

| Displacement Ratio |

Fraction or percentage |

fraction |

The fraction of dissolved solids replaced with shower water. |

| Norden Number |

Fraction or percentage |

fraction |

A coefficient. |

| Species Displacement Ratio |

Fraction or percentage |

fraction |

The fraction of selected compound replaced with shower water. |

The outlet consistency must be positive, and must be less than 0.2.

Option 1 - DR

The mass balance is calculated for every component of the shower and inlet flows as follows:

Cmat = DR * Cshower + (1 - DR) * Cin

where:

Cmat is the solids concentrations (lb/ft3) in the mat

Cshower is the solids concentrations (lb/ft3) in the shower

Cin is the solids concentrations (lb/ft3) in the inlet.

All solids (pulp, etc.) are assumed to leave with the mat.

Option 2 - NN

In this case DR is predicted using the Norden Number.

All other calculations are performed with the predicted DR.

Temperature behavior is correlated with the default DR unless different DR is given.

If selected, one dissolved solid can have lower or higher displacement ratio meaning it will be washed out from the pulp stream with higher or lower efficiency.

Zero flow in Pulp stream!

Zero flow in Pulp stream!

Solution: Set nonzero inlet flow.

Zero flow in Shower stream!

Zero flow in Shower stream!

Solution: Set nonzero inlet flow.

Missing Stream(s)!

Missing Stream(s)!

Solution: check if all streams are connected to the equipment.

Invalid Mat Consistency!

Invalid Mat Consistency!

Solution: Consistency should be between 0 and 1.

Invalid Default DR and/or Norden Number!

Invalid Default DR and/or Norden Number!

Solution: DR should be between 0 and 1; Norden Number is positive.

Warnings

Warnings  Errors

Errors

Invalid Default DR and/or Norden Number!

Invalid Default DR and/or Norden Number!