|

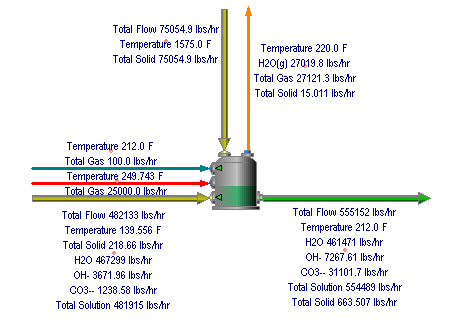

The Smelt_Dissolving_Tank dissolves smelt by mixing a hot smelt stream with a cold weak wash stream. A green liquor stream and a steam stream result.

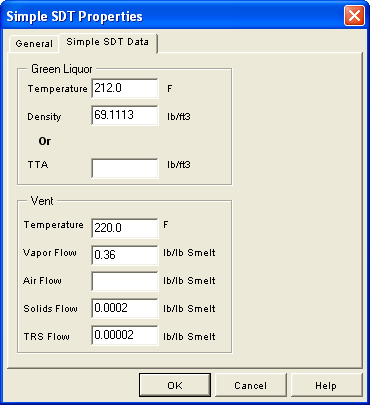

Specify either the Green Liquor Density or the Green Liquor TTA.

The required inlet flow of weak wash is calculated and the inlet weak wash stream flow is set to this value.

|

What do you want to see?

|

|

|

Data |

Unit |

Description |

|

Set |

Item |

Type |

Native |

|

Equipment Properties |

GLTemperature |

Temperature |

F |

The temperature of the raw green liquor. |

| GLDensity |

Density |

lb/ft3 |

The density at 25 C of the raw green liquor. |

| GLTTA |

Density |

lb/ft3 |

The TTA at 25 C of the raw green liquor. |

| VaporFlow |

|

|

Vapor flow to the vent, lb/lb smelt. Vapor flow at the stack is typically 0.357 lb/lb smelt. Stacks are usually 30-40% moisture. |

| VentTemp |

Temperature |

F |

Temperature of vent. 212 F at the stack after the scrubber. Vent temperature should be higher. |

| AirFlow |

|

|

Air flow, lb/lb smelt. 1.4 lb air/lb smelt at the stack. No CO2 in stack gas. |

| VentTRS |

|

|

The flow of TRS (H2S) in the vent, lb/lb smelt. 3.3x10^-5 lb/lb smelt after the scrubber. 50 times that in the vent? |

| VentSolids |

|

|

Solids flow to the vent, lb/lb smelt. 110x10^-4 lb/lb smelt to the scrubber. 1.98x10^-4 lb/lb smelt after the scrubber. |

The smelt dissolving tank dissolves smelt by adding weak wash. The amount of weak wash used is set by specifying the green liquor density or TTA. It is assumed that the resulting raw green liquor is saturated. Thus additional weak wash must be added to cool the resulting green liquor to saturation by evaporation. The evaporated water is vented.

No weak wash entering!

No weak wash entering!

Solution: Set a nonzero weak wash flow.

Missing Stream(s)!

Missing Stream(s)!

Solution: check if all the streams are connected to the equipment.

No smelt entering!

No smelt entering!

Solution: Set a nonzero smelt inlet flow.

Need Green Liquor Density or TTA!

Need Green Liquor Density or TTA!

Solution: Set one of these properties.

Calculation Failed!

Calculation Failed!

Solution: Model cannot calculate the necessary weak wash. Check the settings.

Warnings

Warnings  Errors

Errors

Need Green Liquor Density or TTA!

Need Green Liquor Density or TTA!