|

Data |

Unit |

Description |

|

Set |

Item |

Type |

Native |

|

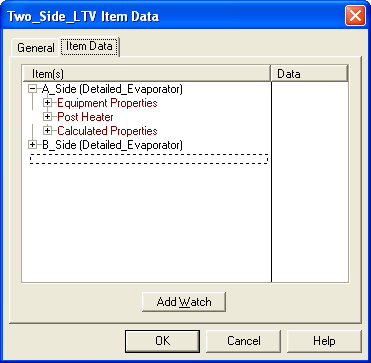

Equipment Properties |

Dome Pressure |

Pressure |

psia |

Pressure of Liquor_Out and Steam_Out streams. If given with Area the Heat Transfer Coefficient is calculated. |

| Heat Transfer Coefficient |

Heat Trans Coef |

BTU/hr/F/ft2 |

If given with Area the Dome Pressure is calculated. |

| Area |

Area |

ft2 |

Heat transfer Area. |

| Energy Efficiency |

Fraction or Percent |

Fraction |

Fraction of available energy transferred to the liquor. |

|

Post Heater |

Heat Transfer Coefficient |

Heat Trans Coef |

BTU/hr/F/ft2 |

If given Area must also be given. |

| Area |

Area |

ft2 |

If given Heat Transfer Coefficient must also be given. |

| Delta T |

Temperature Change |

Delta F |

Change in temperature from Post_Heater_Liquor_In to Post_Heater_Liquor_Out. |

| Pressure |

Pressure |

psia |

Post heater pressure. Defaults to Post_Heater_Liquor_In pressure. |

|

Calculated Properties |

Dome Pressure |

Pressure |

psia |

The dome pressure of the evaporator, calculated if the Heat Transfer Coefficient is given. |

| Heat Available for Transfer |

Energy Flow |

BTU/hr |

This is the heat input to the evaporator body, SI * Hstm |

| Evap Heat Transfer Coef |

Heat Trans Coef |

BTU/hr/F/ft2 |

The heat transfer coefficient calculated for saturated liquor, assuming the logarithmic average temperature difference between the inlet and outlet flows. It is taken in account that the heat transferred is the latent heat of steam and, usually, the evaporators are working with a constant delta T. |

| Evap Delta T |

Temperature Change |

Delta F |

Condensate_Out temperature minus Liquor_Out temperature. |

| Evap Heat Transferred |

Energy Flow |

BTU/hr |

The heat transferred to evaporator (a part of the total available heat). |

| BPR |

Temperature |

F |

The boiling point rise of the outlet liquor. |

| Post Heater Heat Trans Coef |

Heat Trans Coef |

BTU/hr/F/ft2 |

Heat transfer coefficient, calculated for post heater. |

| PH LM Delta T |

Temperature Change |

Delta F |

Logarithmic average temperature difference, calculated for post heater. |

Warnings

Warnings  Errors

Errors