What do you want to see?

|

|

Data Description

| Data | Unit | Description | ||

| Set | Item | Type | Native | |

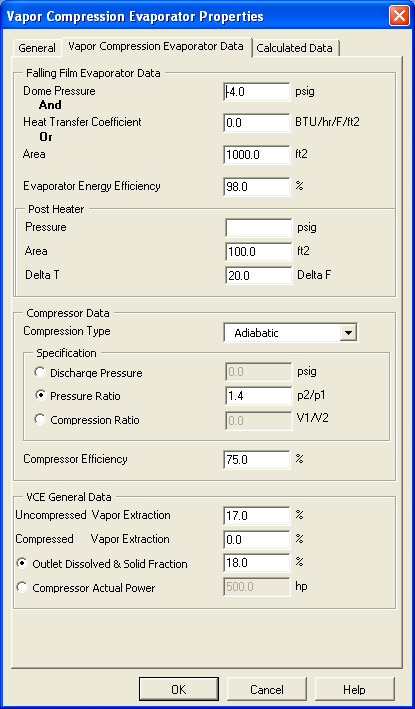

| Equipment Properties | Dome Pressure | Pressure | psia | Pressure at the top of the evaporation space. Also the pressure of Liquor_Out stream. |

| Heat Transfer Coefficient | Heat Trans Coef | BTU/hr/F/ft2 | Heat Transfer Coefficient of the evaporator zone. If given, the heat transfer Area is calculated. | |

| Area | Area | ft2 | Heat transfer Area of the evaporator zone. If given, the Heat Transfer Coefficient is calculated. | |

| Energy Efficiency | Fraction or Percent | Fraction | Fraction or percent of the available energy transferred to the evaporating liquor. | |

| CompressionType | The type of the compression process regarding the heat exchange with the environment. Adiabatic Compression accounts no heat exchange with the environment. Polytropic Compression takes into account the losses due to thermodynamic cycle efficiency. | |||

| Option | Specify how to calculate the the compressor's discharge pressure. Discharge Pressure input the specified value. Pressure Ratio input the discharge to suction pressures ratio. Compression ratio input the discharge to suction volumes ratio. | |||

| DischargePressure | Pressure | psia | Discharge Pressure input the specified value for the compressor. | |

| PressureRatio | Pressure | psia | Pressure Ratio input the discharge to suction pressures ratio for the compressor. | |

| CompressionRatio | Compression ratio input the discharge to suction volumes ratio of the compressor. | |||

| Efficiency> | Fraction or Percent | Fraction | The polytropic Efficiency is defined as the ratio of polytropic work to actual work. The adiabatic (isentropic) Efficiency is defined as the ratio of adiabatic (isentropic) work to actual work. | |

| Generated Vapor Fraction | Fraction or Percent | Fraction | Generated Vapor Fraction is the fraction or percent of the evaporated vapor mass flow extracted according to the user request. | |

| Compressed Vapor Fraction | Fraction or Percent | Fraction | Compressed Vapor Fraction is the fraction or percent of the compressed vapor mass flow extracted according to the user request. | |

| VCEOption | Fraction or Percent | Fraction | Specify if the equipment will be controlled to achieve an input Compressor Actual Power or an input Outlet Dissolved & Solids Fraction or percent. | |

| DissSolidFractionOut | Fraction or Percent | Fraction | Specify the input Outlet Dissolved & Solids Fraction or percent. The Compressor actual Motor Power is calculated.> | |

| MotorPower | Work | BTU/hr | Specify the input Compressor actual Motor Power. The Outlet Dissolved & Solids Fraction or percent is calculated | |

| Post Heater Properties | Heat Transfer Coefficient | Heat Trans Coef | BTU/hr/F/ft2 | Heat Transfer Coefficient of the post-heater zone. If given, the heat transfer Area of the post-heater zone is calculated. |

| Area | Area | ft2 | Heat transfer Area of the post-heater zone. If given, the Heat Transfer Coefficient of the post-heater zone is calculated. | |

| Delta T | Temperature Change | Delta F | The temperature change from Post_Heater_In to Post_Heater_Out streams. | |

| Pressure | Pressure | psia | Outlet and inside Pressure of the post-heater. The Post_Heater_In stream pressure is used by default. | |

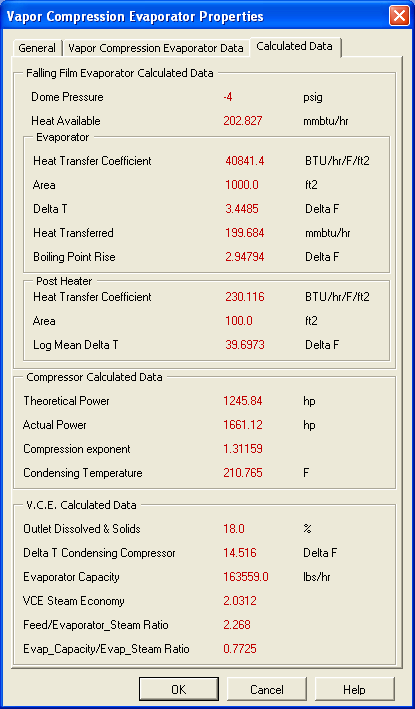

| Calculated Properties | Dome Pressure | Pressure | psia | Pressure at the top of the evaporation space. Also the pressure of Liquor_Out stream. |

| Heat Available for Transfer | Energy Flow | BTU/hr | The heat input to the equipment. | |

| Evap Heat Transfer Coef | Heat Trans Coef | BTU/hr/F/ft2 | The heat transfer coefficient calculated for the saturated liquor in the evaporation zone, assuming the logarithmic average temperature difference between the inlet and outlet flows. Evaporator heat transfer area is input. | |

| Evap Delta T | Temperature Change | Delta F | Temperature difference between the evaporator inlet saturated vapor and the Liquor_Out temperature at saturation. | |

| Evap Heat Transferred | Energy Flow | BTU/hr | The heat transfer coefficient calculated for the saturated liquor in the evaporation zone, assuming the logarithmic average temperature difference between the inlet and outlet flows. Evaporator heat transfer area is input. | |

| BPR | Temperature Change | Delta F | The boiling point rise of the outlet liquor. | |

| Post Heater Area | Area | ft2 | The heat transfer area calculated for the saturated liquor in the post-heater zone, assuming the logarithmic average temperature difference between the inlet and outlet flows. The post-heater heat transfer coefficient is input. | |

| Post Heater Heat Trans Coef | Heat Trans Coef | BTU/hr/F/ft2 | The heat transfer coefficient calculated for the saturated liquor in the post-heater zone, assuming the logarithmic average temperature difference between the inlet and outlet flows. The post-heater heat transfer area is input. | |

| PH LM Delta T | Temperature Change | Delta F | The post-heater mean logarithmic temperature difference. | |

| TheoreticalPower | Work | BTU/hr | The theoretical compression work. | |

| ActualPower | Work | BTU/hr | The actual compression work, taking into account the compressor efficiency. | |

| Gamma | Adiabatic (Isentropic) or Polytropic compression exponent. | |||

| CondensingTemperature | Temperature | F | The condensing temperature of the compressor's discharge stream. | |

| DissSolidFractionOut | Fraction or Percent | Fraction | The final calculated Outlet Dissolved & Solids Fraction or percent. | |

| Delta T Cond Compressor | Temperature Change | Delta F | The temperature difference between the saturated discharge stream and the suction stream of the compressor. | |

| EvapCapacity | Mass Flow | lbs/hr | The mass flow rate of the evaporated vapor at the evaporator outlet. | |

| VCEEconomy | The steam economy of the vapor compression evaporator, calculated by dividing the evaporated vapor mass flow rate with the apparent inlet steam. The apparent inlet steam is the make up steam added to an amount of make up steam energy-equivalent of the compressor actual work. | |||

| FeedPerSteamRatio | The mass flows ratio of the Liquor_In and vapor at the evaporator section inlet. | |||

| CapacityPerSteamRatio | The mass flows ratio of the generated vapor and the vapor at the evaporator section inlet. | |||

Equipment Properties

|

|

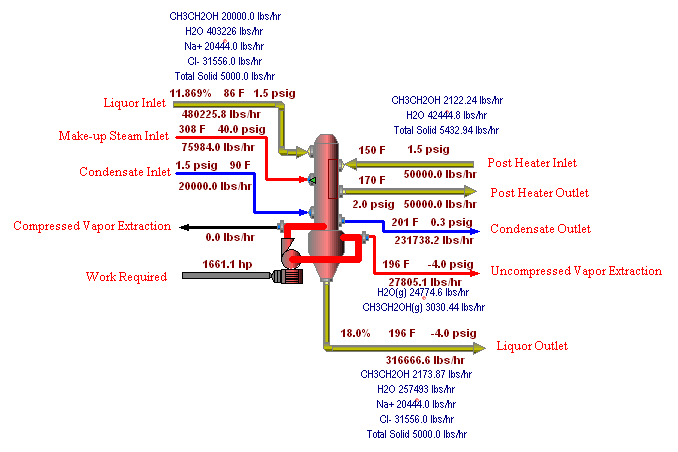

Example of using equipment

|

Method&Equations

The model calculates the unknown variables based on the following thermal balance on the falling film evaporator as follows:

(Q_steamInEvaporator + Q_condensateIn - Q_condensateOut) * Evaporator Energy Efficiency = q_trans =

= (Q_steamOutEvaporator + Q_liquorOut - Q_liquorIn) + q_trans_PH

The heat transfer for the evaporator section is calculated as follows:

q_trans – q_trans_PH = U_EVAP * A_EVAP * LMTD_Evap

The heat transfer for the post heater section is calculated as follows:

q_trans_PH = U_PH * A_PH * LMTD_PH

Both for the evaporator and the post heater sections the log mean temperature difference (LMTD) is calculated as follows:

LMTD = (deltaT_A - deltaT_B) / ln(deltaT_A / deltaT_B)

where A and B are the inlet and the outlet of the heat exchange zone.

The compressor can simulate two compression types which raise the temperature at the discharge end: adiabatic (when no heat is transfered to the environment) or polytropic (characterizing the real compressors when part of the accumulated heat due to the compression is released).

To see the Method&Equations used for the compressor section, please follow the next link:

VCE Steam Economy = Evaporator Capacity / Apparent_Steam_Inlet

Apparent_Steam_Inlet = Make_Up_Steam + Actual Compressor Power / Make_Up_Steam_Latent_Heat

where:

Q_steamInEvaporator is the heat input with the primary vapor

Q_condensateIn is the heat input with the secondary condensate (Condensate_In stream)

Q_condensateOut is the heat output with the primary condensate (Condesate_Out stream)

Q_steamOutEvaporator is the heat output from the evaporator with the secondary vapor

Q_liquorIn is the heat input with the feed Liquor_In stream

Q_liquorOut is the output heat with the Liquor_Out stream

q_trans is the heat total heat transferred in the evaporator

q_trans_PH is the teat transferred only to the post heater

Evaporator Capacity is the vapor flow extracted from the evaporator section

Feed / Evaporator_Steam Ratio is the Liquor_In total flow divided by the evaporator inlet vapor flow

Evaporator_Capacity / Evaporator_Steam Ratio is the vapor outlet flow divided by the evaporator inlet vapor flow

Warnings

Warnings

Evaporator Energy Efficiency should be between (0...1] Fraction or (0...100] %!

Evaporator Energy Efficiency should be between (0...1] Fraction or (0...100] %!

Compressor Efficiency should be between (0...1] Fraction or (0...100] %!

Compressor Efficiency should be between (0...1] Fraction or (0...100] %!

Uncompressed Vapor Extraction should be between [0...1] Fraction or [0...100] %!

Uncompressed Vapor Extraction should be between [0...1] Fraction or [0...100] %!

Compressed Vapor Extraction should be between [0...1] Fraction or [0...100] %!

Compressed Vapor Extraction should be between [0...1] Fraction or [0...100] %!

Outlet Dissolved & Solid Fraction should be between [0...1] Fraction or [0...100] %!

Outlet Dissolved & Solid Fraction should be between [0...1] Fraction or [0...100] %!

Please input Evaporator Heat Transfer Coefficient or Area !

Please input Evaporator Heat Transfer Coefficient or Area !

Compressor Actual Power cannot be selected when Uncompressed Vapor Extraction = 100% !

Compressor Actual Power cannot be selected when Uncompressed Vapor Extraction = 100% !

Compressor Actual Power should be greater than 0 !

Compressor Actual Power should be greater than 0 !

No steam entering. Default LP Steam will be used (40 psig; 308 F)!

No steam entering. Default LP Steam will be used (40 psig; 308 F)!

Default Make Up Steam composition. LP Steam is used (40 psig; 308 F)!

Default Make Up Steam composition. LP Steam is used (40 psig; 308 F)!

Missing Post Heater Inlet stream!

Missing Post Heater Inlet stream!

Compressor Actual Power is too large !

Compressor Actual Power is too large !

The condensate temperature at saturation is higher than the inlet steam temperature !

The condensate temperature at saturation is higher than the inlet steam temperature !

The condensate saturated temperature is lower than the outlet liquor temperature !

The condensate saturated temperature is lower than the outlet liquor temperature !

The outlet liquor's boiling point rise is over 10 F !

The outlet liquor's boiling point rise is over 10 F !

Vapor condensing temperature lower than the liquor flashing Temperature !

Vapor condensing temperature lower than the liquor flashing Temperature !

Total solids exceeded 94%! Fouling may occur inside the evaporator !

Total solids exceeded 94%! Fouling may occur inside the evaporator !

Compressed secondary steam is available in excess !

Compressed secondary steam is available in excess !

Wrong pressure ratio! Calculation aborted.

Wrong pressure ratio! Calculation aborted.

Wrong compression ratio! Calculation aborted.

Wrong compression ratio! Calculation aborted.

The specified compression ratio cannot be established. Over critical conditions.

The specified compression ratio cannot be established. Over critical conditions.

Errors

Errors

Missing Liquor Outlet stream !

Missing Liquor Outlet stream !

Missing Make Up Steam inlet stream !

Missing Make Up Steam inlet stream !

Missing Condensate Outlet stream !

Missing Condensate Outlet stream !

Missing Uncompressed Vapor Extraction outlet stream !

Missing Uncompressed Vapor Extraction outlet stream !

Missing Compressed Vapor Extraction outlet stream !

Missing Compressed Vapor Extraction outlet stream !

Missing Post Heater Outlet stream !

Missing Post Heater Outlet stream !

No dissolved & solids in the inlet liquor! Outlet Dissolved & Solid Fraction option cannot be used !

No dissolved & solids in the inlet liquor! Outlet Dissolved & Solid Fraction option cannot be used !

Make Up Steam stream is too cold to evaporate the Inlet Liquor Stream !

Make Up Steam stream is too cold to evaporate the Inlet Liquor Stream !

Make Up Steam stream is colder than its saturation temperature !

Make Up Steam stream is colder than its saturation temperature !

Compressor section from Vapor Compression Evaporator did not converge !

Compressor section from Vapor Compression Evaporator did not converge !

No vapor entering in the compressor section of Vapor Compression Evaporator !

No vapor entering in the compressor section of Vapor Compression Evaporator !

Compressor Actual Power is too large !

Compressor Actual Power is too large !

Vapor Compression Evaporator did not converge !

Vapor Compression Evaporator did not converge !