|

The LIME-KILN simulates the calcining of lime mud to lime by the following reaction:

CaCO3 --> CaO + CO2

In addition the side reaction

2CaCO3 + 2SO2 + O2 --> 2CaSO4 + 2CO2

can be included.

The fuel flow and air flow required are calculated. The modeling of satellite coolers can be handled indirectly by adjusting the exit temperatures. However, settling chambers and scrubbers must be handled with separate models.

|

What do you want to see?

|

|

|

Data |

Unit |

Description |

|

Set |

Item |

Type |

Native |

|

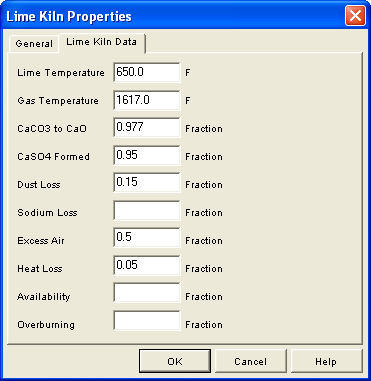

Equipment Properties |

LimeTemp |

Temperature |

F |

The exiting lime temperature. |

| GasTemp |

Temperature |

F |

The exiting gas temperature. |

| CaCO3ToCaO |

Fraction or Percent |

Fraction |

The fraction of total inlet CaCO3 converted to CaO and CaSO4. |

| CaSO4Formed |

Fraction or Percent |

Fraction |

The amount of CaSO4 formed from CaCO3 expressed as a fraction of the total mass flow of incoming elemental sulfur. |

| DustLoss |

Fraction or Percent |

Fraction |

The fraction of the incoming solids lost as dust. |

| SodiumLoss |

Fraction or Percent |

Fraction |

The fraction of the incoming sodium lost as dust. |

| ExcessAir |

Fraction or Percent |

Fraction |

The excess air required as a fraction. |

| HeatLoss |

Fraction or Percent |

Fraction |

The heat loss through the kiln shell as a fraction of the fuel heating value. |

| Availability |

Fraction or Percent |

Fraction |

The availability of the exiting lime as a fraction, where availability = mass CaO / total lime stream mass. The default is to calculate the availability based on no overburning. Note: It is recommended that initially you don't specify availability, but let the block calculate it. Otherwise, it is possible that the system can be over specified. |

| Overburning |

Fraction or Percent |

Fraction |

The fraction of the total CaO exiting that becomes overburned. The default is to assume no overburning and calculate availability. Overburning will only be used if the availability is not specified. |

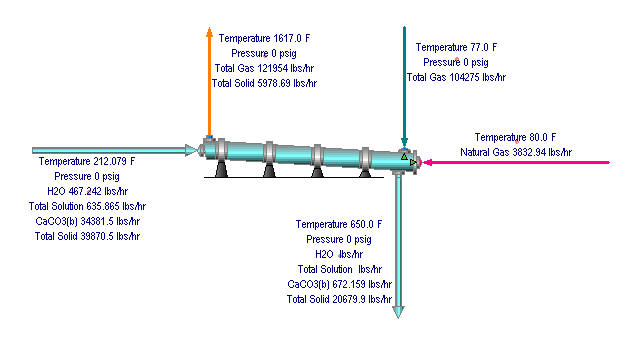

The material and energy balance calculations for the lime kiln are performed iteratively. A fuel flow value is guessed and the resulting flue gas and lime stream flows are calculated. By adjusting the fuel flow until the conservation of mass and energy are obeyed, the correct value is obtained.

First non-iterative material and energy balance calculations are performed. The dust loss component flows are calculated and removed from the rest of the burden. Then the unreacted CaCO3 is calculated. Next the total enthalpies for the mud and make-up and the mass enthalpy for the fuel are calculated. Finally the heat of combustion of the fuel and the heat due to de-slaking are calculated.

After the non-iterative calculations, the iterative calculations are performed. The elemental flows of C, H, S and O are calculated. Then the CaSO4 formed and the CaO reaction products and any overburning are calculated. The form of sodium lost in the dust (as Na2SO4 and/or Na2CO3) is determined. To complete the material balance, the flows of H2O CO2 and SO2 are determined (from the inlet elemental flows) and the air stream component flows are calculated.

The final step is to finish the iterative energy balance. The total enthalpies of the two outlet streams and the fuel and air streams are calculated. From this the difference between the total enthalpy in and the total enthalpy out can be calculated and checked for convergence. If convergence has not been achieved, a new fuel flow value is guessed based upon the size of the difference. The iterative calculations are repeated (with a new guess for fuel flow) until convergence is achieved.

Missing Stream(s)!

Missing Stream(s)!

Solution: check if all the streams are connected to the equipment.