Energy Integration

Our Pinch Technology Studies identify all possible energy savings available at a

site and their corresponding financial benefits.

Since 1995, American Process has applied specialized energy cost minimization techniques

to industries such as pulp & paper, ethanol, petrochemicals, steel, kaolin, textiles,

and waste-to-energy. We have completed over 350 energy integration studies and identified

annual energy savings opportunities of over one billion dollars.

American Process boasts the world’s largest experience list for the application

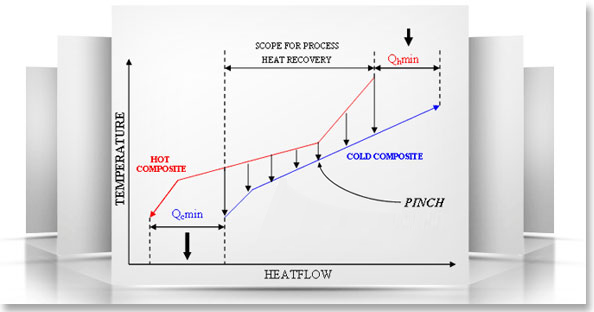

of Pinch Technology to industry. Pinch Technology is a systematic, thermodynamics-based analysis of industrial processes that defines the minimum amount of thermal

energy needed to run the facility and identifies the best way to reach this usage

level through operational changes and heat recovery projects. Our Pinch Technology

Studies identify all possible energy savings available at a site and their corresponding

financial benefits.

API improved Pinch concept

At American Process we have revolutionized the way Pinch analysis is applied to

industry.

Water Close™ and O-Pinch® (Operational Pinch), were developed as American Process

Inc add-in methodologies to traditional Pinch technology. They are used to identify

water savings opportunities (WaterClose™) and operations-based energy saving opportunities

requiring low or no capital cost (O-Pinch®).

Success stories

-

Process Integration Study by American Process saves over $600,000 from annual energy costs in Northern Pulp Pictou mill

American Process conducted a Process Integration study for Northern Pulp Pictou

mill. The study involved the development and validation of a mill wide simulation

model, an operational Pinch and thermal Pinch analysis, with the objective to identify

the short and long term opportunities for energy savings at the mill.

Read more ...